The term "full bleed" describes edge-to-edge graphics extending beyond trim lines. Commonly practiced in the paper media printing industry, this method ensures complete design coverage of the finished product. Although we produce graphics on textiles and other soft goods not paper media, the same principle is applied to achieve full coverage designs.

After graphic designs and textile selection is finalized, the following steps ensure only high-quality products leave our facility and reach the customer.

step 1: Dye Sublimation Printing

We leverage dye sublimation to create customized textiles and soft goods used for manufacturing athleticwear, active casual apparel, signage, promotional goods, and many other applications. This first step of production involves printing your designs onto a special carrier paper using dye sublimation inks. We achieve continuous printing by using a take-up reel to tightly wrap printed paper onto a carrier tube, making long panels of dye sublimated textiles possible. This method can be used to process any batch size from one piece to many hundreds of pieces, as well as continuous banners and signage. Due to inherent flexibility, dye sublimation allows for short or long production runs to serve a wide range of customer needs.

At this stage, printed colors appear somewhat dull on the paper. Don’t be fooled!

Step 2: Dye Sublimation Transfer

Next, we pass the printed paper through our rotary heat press in direct contact with the specified polyester based textile. Under heat and pressure, dye particles suspended within the printed ink transition directly from a solid to a gas. This is the chemical phase transition process of sublimation, where all the magic happens! The design is now part of the textile, showing vibrant and vivid colors.

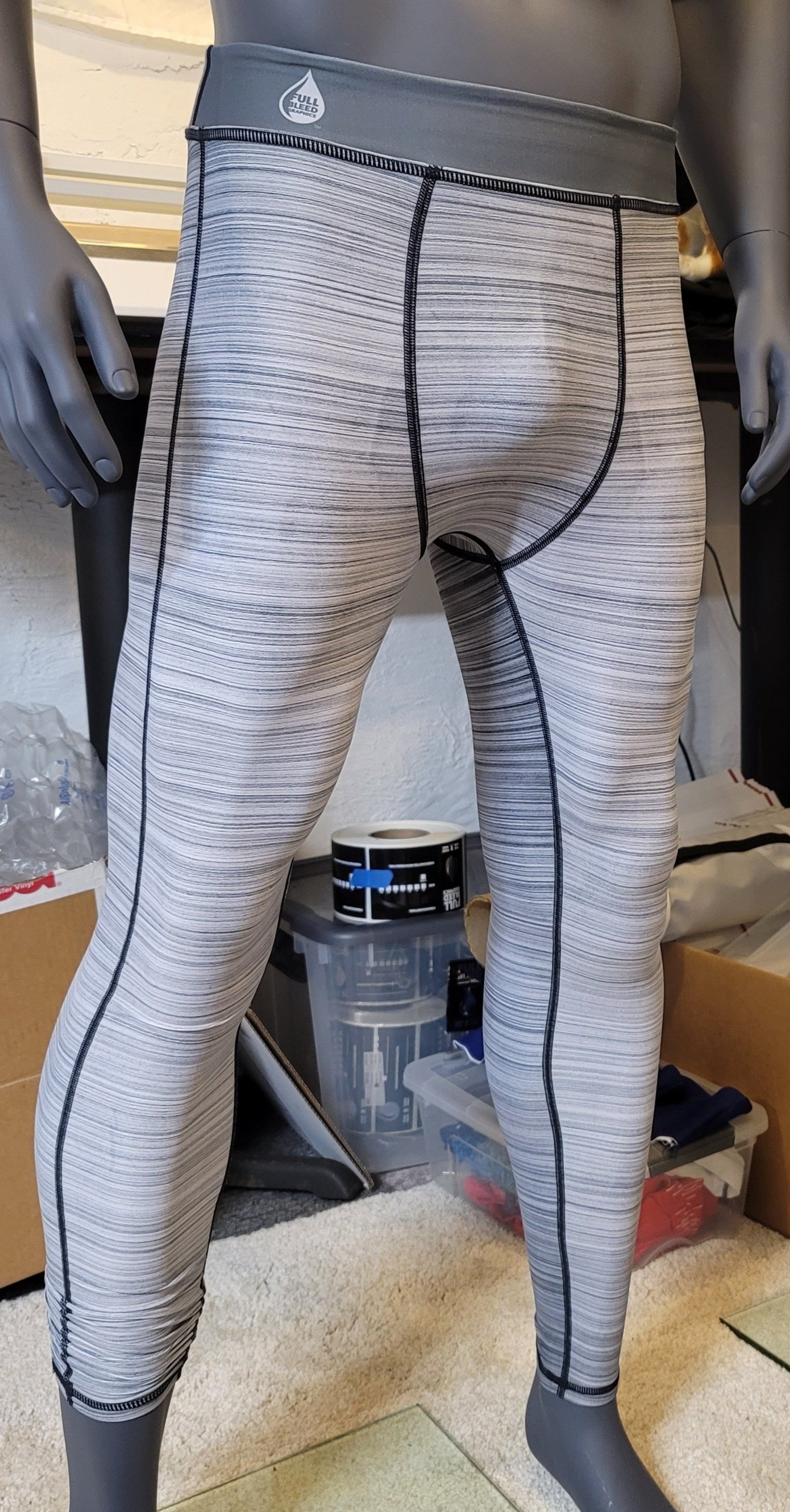

Cooling occurs while exiting the heat press, setting and embedding the dyes into individual textile fibers. This feature is unique to dye sublimation. With screen printing or vinyl transfers, you will feel the image because it sits on top of the textile surface. With dye sublimation you will not feel the image and it will not crack, fade, or peel like other customization methods. Designs will move with and stretch to the limit of any high performance textile. Dye sublimation is perfect for the athletic apparel industry for this reason.

STEP 3: Cutting

After designs are transferred via dye sublimation, each individual panel is cut. This step is as simple as it sounds. The textile is cut along trim lines, stacked for handling, and prepared for assembly.

STEP 4: sewing

Cut panels are joined using industrial sewing machines. Depending on design and features, different sewing machines will be used to achieve ideal durability and performance. Just like all previous steps of manufacturing, we perform sewing in-house to ensure the best possible result is achieved for our customers.

After sewing each item is inspected for quality, folded, tagged, and bagged for delivery. No international production, no middlemen, strictly made in the USA. Manufactured in Minneapolis, Minnesota with pride!

Our Promise

We'll only work with the best materials and equipment available. We never compromise quality. We strive for honest customer service, total satisfaction, and an enjoyable creation experience for all clients. All Full Bleed Graphics products are proudly manufactured in our Minneapolis, MN facilities. Made in the USA!

GET A Custom quote

Ready to start creating unique custom items? Enter your information and we will contact you shortly!